Dust is a problem in any indoor space. It can be unsightly, can affect the respiratory lungs of the occupants. Most dust is also a combustible hazard that require special handling of the dust. This includes special options on the dust collector which include explosion vents, suppression vents, and no return isolation valves.

Also, good house keeping is a must to keep non captured dust to be cleaned periodically so compatible dust are not left on surfaces. NFPA 68 has since 2007 required all dust to be tested to determine the explosiveness of the dust. If the dust is not explosive then the controls as stated above are not required on dust collectors, and on dust collectors under 8 cubic feet of the dirty side of the enclosure are exempt. Also, one other exemption is the under 5000 cfm wood dust collector’s on wood dust are also exempt of controls on most instances.

Last year 2021 NFPA 652 mandated all companies with dust collection systems to provide a Dust Hazards Analysis DHA. This is a complete analysis that includes the dust test and specific hazards analysis for that plant and operation. Typically done by a registered engineer and can cost from $6000 to $20,000. The reason for these mandates is the explosions of dust in plants across the country.

That is why AAir Purification Systems designs, builds, tunes, and maintains top-quality industrial dust collection systems for use in a wide range of commercial spaces. But how does an industrial dust collection system work?

How Industrial Dust Collection Systems Work

For a start, it is important to note that there are different types of dust collection systems. While one might be as good as another in certain circumstances, each type is best suited to highly specialized processes and in specific situations where a certain dust removal capacity is called for.

Types of Dust Collection

- Sanding Dust Collection

- Grinding Dust Collection

- Buffing Dust Collection

- Abrasives Bead Blast Dust Collection

- Multi-Operation CNC Dust Collection

- Combined Sanding & Grinding

- Battery Plant Dust Collection

- Plasma Fume Collection

- Wood Dust Collection

- Titanium, Magnesium, Zerconium Grinding Dust Collection

- Product Conveyance Dust Collection

- Food Powder Dust Collection

- Vitamin, Food, & Supplement Dust Collection

- Pharmaceutical Dust Collection

- Carbon Fiber Dust Collection

- Plastic Collection

Types of Dust Collection Systems

- Agricultural

- Blasting

- Chemical Processing

- Fiberglass

- Fibrous/Fluffy Dust

- Food Processing

- Glass

- Laser Cutting

- Machining

- Metalworking

- Metalworking – Forging and Recycling

- Paper Scrap

- Pharmaceutical

- Plasma Cutting

- Powder

- Retrofits

- Rubber Grinding

- Sanding/Grinding/Sawing

- Seed Processing

- Thermal Spray

- Welding – Ambient Fume

- Welding – Source Capture

- Woodworking

Treating Dust Laden Air

The primary components of a dust collection system are a dust filter, a blower, a receptacle, a dust removal system, and a cleaning system. Like any air filtration system, a dust collector works by circulating air that is contaminated with dust and pushing it through or over a filter. Different types of filters and different levels and arrangements of air circulation or suction power are used to achieve this.

Typically, the dust from the treated air will be caught or stopped by the filter as the air comes into contact with it. The dust will then fall into a sediment catcher or it will be mechanically scrubbed, wiped, shaken, or pushed into the sediment collection area.

Dirty air containing dust particles enters the collector through a system of ducts. Then the air comes into contact with a series of angled pieces of metal called baffles which slow the air down to prevent the dust from hitting the filters at a speed that would damage the filters. The air is then moved into the plenum, which is another word for the sediment collector mentioned above.

Capturing Dust

At this point, the air is passed through the cartridge filters. In some systems, these are suspended vertically from a tube sheet, which is the metal sheet that separates the clean and dirty air spaces. The filters are pleated to provide greater surface area for filtration, and some system types use a nanofiber material that is able to filter out especially fine dust particles.

The filters then capture the dust and some of it will fall into the plenum and some will remain stuck to the filters. Gaskets mounted at the apex of each filter for a seal between the filter and a tube sheet which prevents the dust from escaping.

Filter Cleaning

Of course, dust filters must be cleaned from time to time. Some systems use pulses of compressed air to hit the filters. The air moves in the opposite direction from the direction of the incoming air to be filtered, which helps disrupt clinging dust.

Other systems use other means such as shaking. Some need to be removed and can be washed, agitated, or wiped to clean them.

There are a wide variety of dust filter system types. Some are well suited to serving the needs of wood shops. Others work well for paint sanding, and many more are considered ideal for other types of production processes. Where the respiratory health of workers is a concern, personal protective equipment and proper ventilation are important parts of your dust mitigation plan.

To learn more about industrial dust collection systems and obtain a quote on a system designed and optimized for your production space, get in touch with AAir Purification Systems today.

Filter Change Outs

– All filters are sized on an established air-to-cloth/media ratio (cubic feet of air/gas per minute to square feet of filter cloth/media. This is also referred to as filter rate.

– In many cases the end-user will specify a desired air-to-cloth/media ratio, or one will be determined from past experience for testing.

Considerations for establishing the air-to-cloth/media

ratio include:

- Particle size and characteristics

- Application; is it nuisance venting or process collection

- Operating hours

- Inlet grain loading

- Moisture content of the product

- Operating temperature

Common Types Of Dust Collectors

- Shaker Collectors

- Reverse Air Collectors

- High Pressure, Low Volume (Pulse-Jet) Collectors

- Medium Pressure, High Volume Collectors

- Envelope style Shaker units

- Wet Process Collectors

- Electrostatic Precipitators

- Packed Tower Scrubbers

- Spray Tower Scrubbers

- Various Fan Cleaning Collectors

Cyclone Separators

Cyclones are centrifugal devices in which air enters tangentially, causing the material to be forced to the outside of the cone and discharged through a hopper. Clean air exits from the top of the cyclone. Cyclones are sometimes installed in front of a dust collector as a pre-cleaner in high grain loading applications.

Pulse-Jet Cleaning

Pulse-Jet cleaning using compressed air at 90-100 PSIG is the most commonly used method for cleaning filters in both Baghouses and Cartridge dust collectors The major components for this cleaning system include a Timer Board, Solenoids, Diaphragm Valves, compressed air manifold, and Pulse Pipes located above the filters.

A signal is sent from the timer board to the solenoid valve which is connected to the diaphragm valve by a pneumatic tube. When the solenoid valve opens it energizes the diaphragm valve releasing a burst of low volume high pressure air into the pulse pipes. This creates a shock-wave in the interior of the filter bags or cartridges dislodging the dust from the exterior of the filters

Cartridge Collectors

Excluding extremely high temperature applications, Cartridge Collectors can and are used on most dust collecting applications. Because of their wet laid or melt blown manufacturing process, Cartridge Collector media are inherently more efficient than needle punched felted baghouse media. Most Cartridge Collector media are not as dependent on a heavy dust cake on their surface to achieve good efficiencies as is Baghouses.

Serving Clients Throughout Southern California, Mexico, and Arizona

Sanding Dust Collection

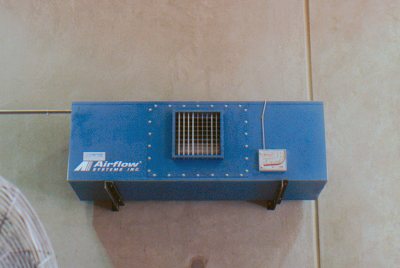

Airflow Systems F-70 R air filtration units in “free hang” application for airborne wood dust from sanding. “Free Hang Systems” may be the perfect approach for airborne dust, smoke, and mist control. This cost-effective approach reduces “breathing zone” dust to keep in compliance with OSHA dust levels.

Grinding Dust Collection

Knife Grinding and Buffing, Dust collection system combines Farr cartridge dust collector and cyclone separator. Cyclone pre-filtration may be used for spark traps and / or heavy loading applications. This particular application had long stringy material.

Buffing Dust Collection

Knife Grinding and Buffing, The operation required no filter replacement for 5 years.

Sanding Dust Collection

Dust collection system for “Badder” sanders of a golf manufacturer includes custom enclosures.

Grinding Dust Collection

Granite / Stone Grinding Operation, Airflow Systems model T140 free-hanging collector filters airborne dust. Other approaches for this type of operation would be a dust control booth or hoods.

Grinding Dust Collection

Granite / Stone Grinding Operation

Multi-Operation Dust Collection

Custom Plastic Application, A Farr Tenkay, cartridge dust collector is ducted to various equipment: saws, grinders, lathes, and mills for a custom plastic operation.

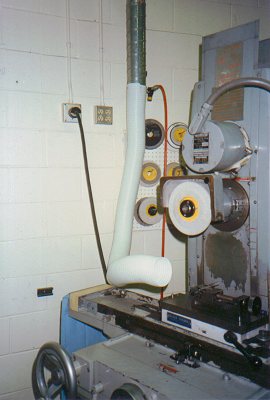

Multi-Operation Dust Collection

Custom Plastic Application, Extractor arm (Airflow EZ Arm II) on lathe operation.

Multi-Operation Dust Collection

Custom Plastic Application, Custom fixtures for plastic milling operation.

Multi-Operation Dust Collection

Custom Plastic Application, Cartridge dust collector handles particulate from saws, grinders, lathes, and mills.

Abrasives Dust Collection

Downdraft tables (Airflow Systems DT3000 units) for abrasives manufacture.

Grinding Dust Collection

Kana Duct Adjustable Nozzle on Surface Grinding Operation.

Grinding Dust Collection

Plymovent R-4 cartridge dust collectors ducted to dual pedestal grinder’s buffers.

Grinding Dust Collection

Plymovent R-4 cartridge dust collectors ducted to dual pedestal grinder’s buffers.

Sanding/Grinding Dust Collection

Sanding and grinding operation ducted to a Plymovent B-4 unit.

Battery Plant Dust Collection

Farr Tenkay 36 cartridge dust collector units ducted to a battery plant in Tijuana, Mexico.

Plasma Dust Collection

Farr GS 16 cartridge dust collectors ducted (through penetration in wall) to custom plasma cutting table.

Wood Dust Control

Farr Big Round Filter for speaker manufacturer in Mexicali, Mexico.

Titanium Grinding Dust Collection

Aerpro custom regain air-grinding booth for aircraft plant. Regain is the vents at the top of the booth which blow dust into the suction inlets at more than 400 feet per minute.

Titanium Grinding Dust Collection

Dust collectors in back of booth are stainless steel collection units for titanium dust.

Grinding Dust Collection

Downdraft Bench used for hand grinding operation.

Sanding Dust Collection

Airflow Systems downdraft table (DTH 800 and 1700 units) with custom enclosure for sanding operations.

Sanding Dust Collection

A Filter 1 downdraft bench removes fiberglass dust for sanding operation for a custom orthopedic brace manufacture. This particular unit has been in operation for more than 10 years.

Dust Conveyance

Custom automatic dumpster cover used with conveying cyclone to move dust from larger dust collection systems into 40-yard dumpster.

Food Powder Collection

Stainless steel backdraft hoods draw dust from a food powder mixing application.

Food Powder Collection

The system is ducted two dust collectors: a Farr GS-16 unit and a GS-24 unit.

Vitamin/Food Supplement Powder Collection

System is equipped with explosion vents to the atmosphere. Ideal for Pharmaceutical Manufacturing as well.

Mixing Dust Collection

Airflow Systems portable dust collector for drawing dust off mixers for a detergent manufacturer.

Mixing Dust Collection

Notice the use of Kana Duct adjustable nozzle strategically placed to remove the plume of dust on the fill sections of the detergent outflow.

Portable Vacuums

Dust Control Tromb unit attached to a suction grinder for shipyard use.

AAir Purification Systems offers encompassing solutions for facilities seeking industrial dust collection systems. We help assess the scope of air contamination in your facilities including dust type, size and amount generated. Then, we provide proven products and complete system installation, tailored to fit your facilities.

We specialize in the development of complex dust collection arms for manufacturing dust collection, including for woodworking, metal fabrication and a broad range of applications. Turn to us for dust collection at-scale, including cartridge collectors, cyclone separators, wet dust collectors, baghouse dust collectors and more.

Turnkey System Development

We’re one of the few companies offering complete dust collection implementation. Our turnkey approach is comprehensive, encompassing every stage of the process. From identifying the right products, to mapping the installation, to implementing the products, we handle everything. Our mission is to provide a tailored solution to your dust collection and air quality management needs.

- Designing

- Installing

- Functionality testing

Broad Range of Applications

Our experience across industries enables us to design and install dust collection systems for just about any application. We specialize in grinding and sanding dust collection, spanning source capture systems, overhead systems and centralized systems. Let us meet the specific demands of your facilities with a turnkey installation.

- Sanding dust collection

- Grinding dust collection

- Abrasives dust collection

- Plasma dust collection

- Multi-operation dust collection

- Food powder collection

Keep Your Dust in Check

For information about dust collection arms and systems or to consult with our experienced team to design the optimal system for your facilities, contact AAir Purification Systems today at 858-578-2825. We have experience across a variety of industries and a reputation for meeting the unique dust collection needs of our customers.

AAir Purification Systems has facilities located in San Diego, CA, as well as Tijuana and Phoenix, with the personnel and crews to serve Southern California, Mexico, and the state of Arizona! Contact us today!